Explosion-proof bridge crane is divided into two categories according to the use of environment, according to the GB3836.1-2000 standard, according to the explosive gas environment is divided into class I and Class II electrical equipment; According to the provisions of GB12476.1-2000, electrical equipment for combustible dust environment is only one class, and the corresponding explosion-proof bridge crane is classified as follows:

Class I: Crane for coal mines

Class II: Cranes for explosive gas environments other than coal mines.

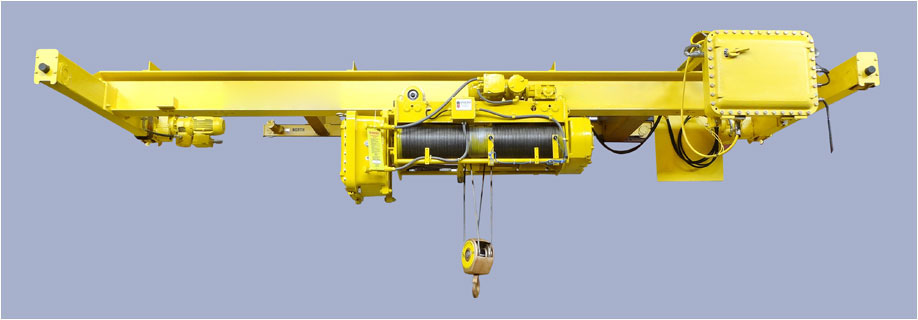

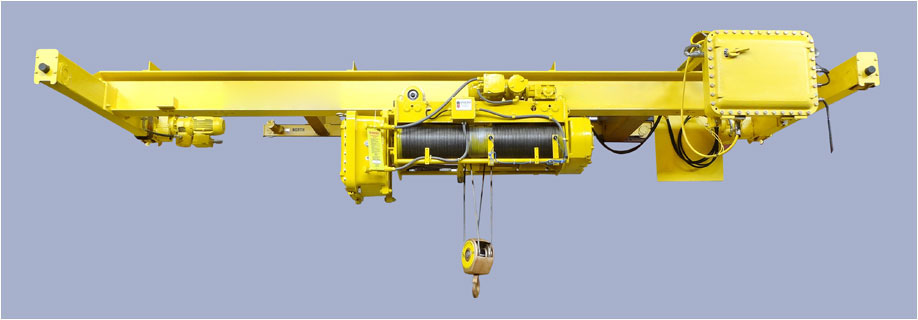

The standard parameters of QB explosion-proof bridge crane are:

Load capacity: 3-50 tons

Span: 10.5-31.5 meters

Lifting height: ≤16

Lifting speed: 2-8 m/min

Car running speed: ≤ 25m/min

Crane running speed: ≤ 25m/min

Job level: A3, A4

The explosion-proof principle of QB type bridge crane is to take corresponding measures to control spark generation. That is, the use of appropriate explosion-proof techniques to control and eliminate electrical and mechanical sparks so that they cannot ignite flammable gas mixtures and environmental areas. Flammable dust and mechanical sparks Special sparkless materials are used to control the content of magnesium and titanium in the light alloy shell in the parts prone to dangerous sparks, so as to avoid collision and friction between relative moving mechanical parts, so as to achieve explosion-proof.